Steel furring channel is a thin strip of metal used to level or raise surfaces, often used in ceiling and wall construction. The section view of these parts maybe profiles as letter C,U, Omega(Ω), A , and etc, so as to meet the needs of various construction scenarios.

Steel Furring is the standard description of these products in China’s conctrction industry. Besides this official name, other descriptions can be also find in internet, such as keel, joist, and etc.

A furring channel can create a level surface for attaching finishing materials, providing space for insulation and air circulation. It is crucial for optimizing surface preparation, enhancing insulation, and supporting construction efficiency. By providing a reliable and effective leveling solution, furring channels support efficient construction, improve surface finish, and contribute to successful project delivery by ensuring that surfaces are well-prepared, aligned with design specifications, and capable of meeting performance criteria and client expectations.

The finishing materials to be attached on the furring channel maybe plaster(Gypsum) board, Aluminum ceiling panel, plastic board, mineral wool ceiling panel.

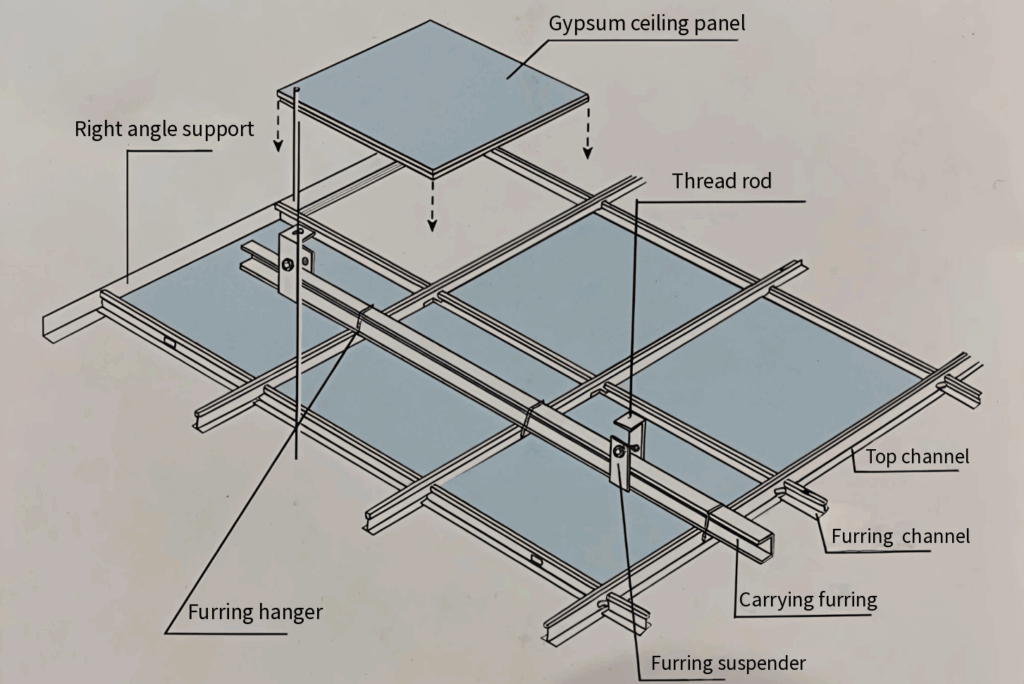

Nomally,a truss of ceiling system is composed by ceiling anchor,thread rod, carrying furring (top furring), nailing furring , and some connectors. The main function of the top furring is to carry most of the weight of the ceiling system, while the function of the nailing furring is to nail the ceiling panels.

In most engineering cases, carrying furring and nailing furring are profile C furring channels for Gypsum board installation. For mineral wool ceiling panel or aluminum panel, the top furring is profile C channel, the nailing furring can be T grid furring, A profile furring or profile Omega(Ω)furring.

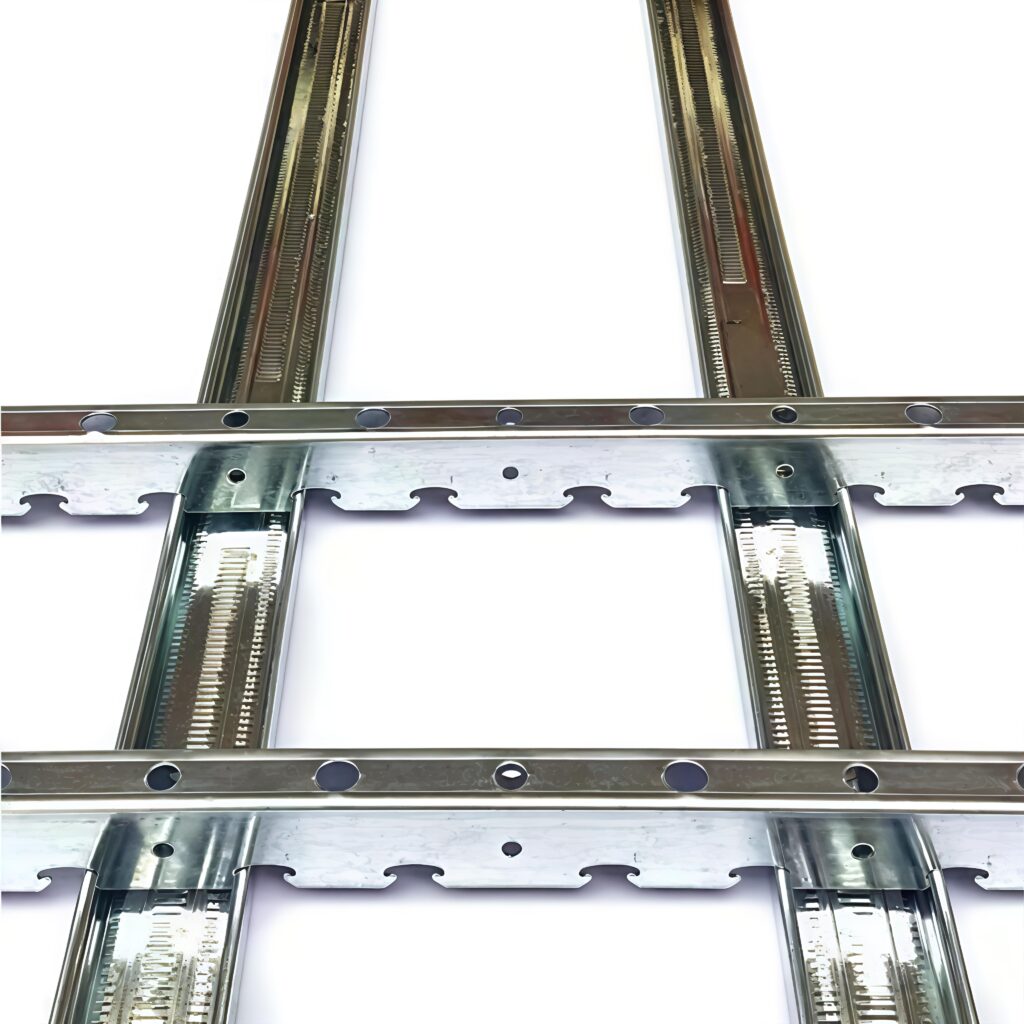

To have a more efficient installation, hanger furring channels are widely used for gypsum board installation recent years, especially in residential building. In the side view of the hanger furring channel, there are some hooks on both sides of the furring channel in regular intervals to nail the nailing furring channel. but in some public engineering projects, only profile C furring channels are accepted, because they can carry more heavy loads than hanger furring channels.